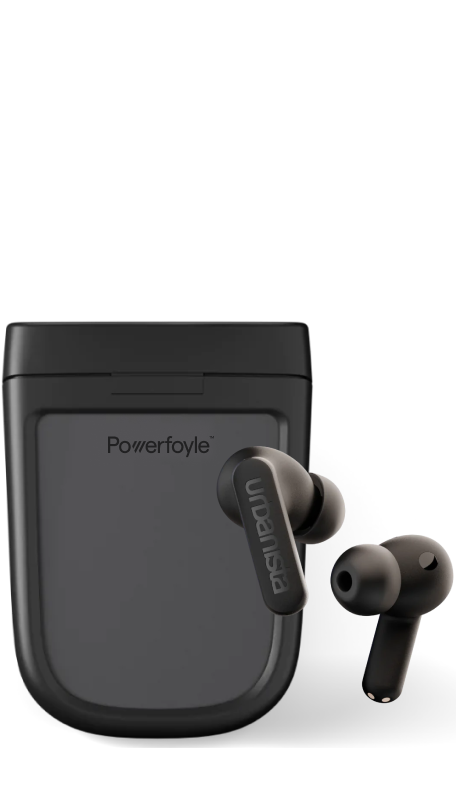

IT’S TIME FOR A BETTER WAY TO POWER YOUR DEVICES.

ENDLESS CLEAN ENERGY USING INDOOR AND OUTDOOR LIGHT

Ultimate convenience with no compromise on design.

No cords.

No disposable batteries.

No charging emergencies.

As featured in